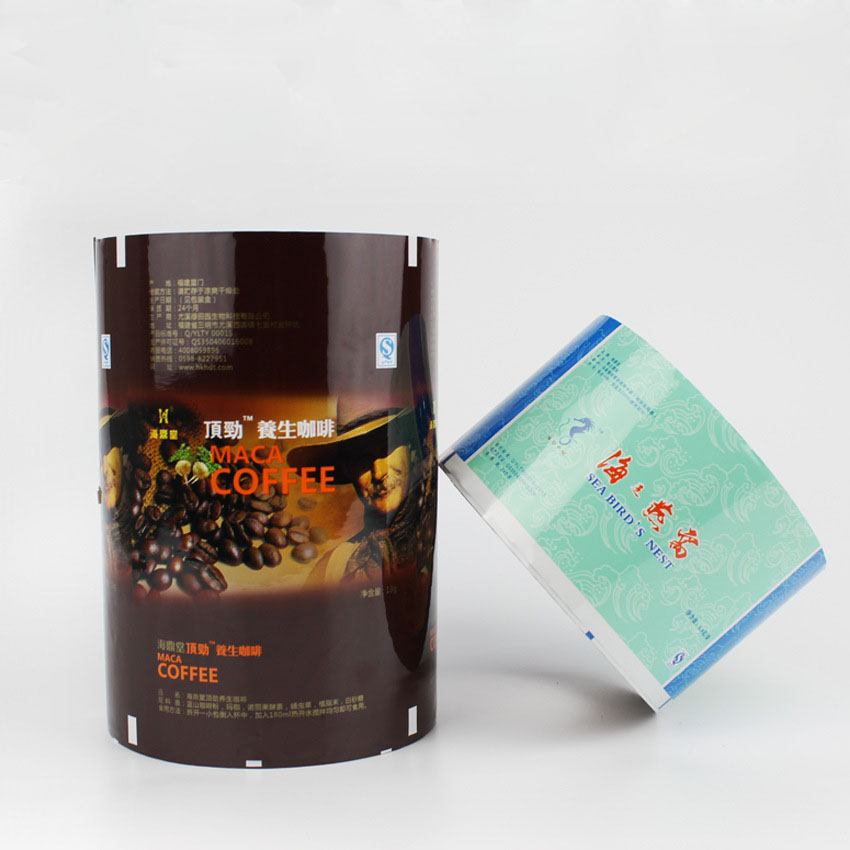

Our Rollstock products offer the following benefits

- Consistent friction properties

- Consistent sealing properties

- Consistent barrier protection

- Consistent color printing

- Reduced down time

- Minimal to no wastage of film

- Quick splicing of a new roll of film

- Faster operating speeds

Description

ROLLSTOCK FILM PRODUCT INFORMATION:

Our custom extruded and laminated films work efficiently with both Vertical form fill and horizontal form fill seal machines.

We configure the rollstock film to suit your application and your budget. All our products are available with the following features:

- Up to 10 color rotogravure process

- Glossy finish, matte finish or a combination finish material

- Reverse printing and surface printing capability

- Easy to open Poly structures also available

HIGH BARRIER FILM LAMINATIONS:

- Available in foil or clear laminations

- Ideal where a high barrier is required from oxygen, moisture, and chemicals

- Longer shelf life

- Maximum durability

- Custom poly film extrusions for excellent sealing

- Alox coating, PVDC, HDPE and EVOH custom extrusions available

METALIZED FILMS LAMINATIONS:

- Excellent barrier properties

- Excellent bonding properties

- Metalized BOPET films

- Metalized BOPP films

- Metalized Polyester films

OPP FILM LAMINATIONS:

- BOPP and High Strength BOPP, CPP Films

- Good dimensional strength

- Good Stiffness

- Resistance to tear and abrasion

- Cost-effective

STICKPACK FILMS:

- Easy tear properties

- Excellent barrier to oxygen & moisture

- Good stiffness properties

- Superior sealing characteristics

- Custom formulations for liquid or powder applications

3 & 6-inch cores

Choose the core size that works best for your brand and your machines.

film winding specification

Choose the direction you want your rollstock wound.

roll sizes

Max outer diameter can be based on imperial or metric measurement or impression count.

co-packer accommodations

Materials are converted based on co-packer needs, including unwind, seals and max outer diameter.